To make my growing season preparations more high tech I built a grow light with more than 25000 lumens light output while spending less than US$300. During the build I posted pictures/short notes on Makers, Hackers, Artists and Engineers Google+ community and received a lot of questions concerning LED choice, drivers, build of materials and construction details. This article is intended to answer these question and hopefully generate others – please don’t hesitate to ask!

The goal of this project was to produce a decent grow light for personal indoor gardening – mainly starting vegetables for subsequent transplanting outside some time in May and possibly extending the grow season in the autumn. While trying to determine necessary light output I realized that good numbers are impossible to find. By reading numerous indoor gardener’s forums I learned that people are having good results with light sources ranging from household-type compact fluorescent bulbs to high pressure sodium street lights. After analyzing pros and cons of all available light sources I decided to use high-power white LEDs. Here’s why:

- They are low-voltage devices therefore they are much safer to work with than HID/fluorescent light sources. Low-voltage (<60V) LED drivers are also inexpensive

- They are efficient as grow lights. Photosynthesis in plants occurs differently under different wavelengths of light; the “good” light is known as Photosynthetically active radiation (PAR). White LED emits most of its light in PAR – out of all light sources it produces most “PAR lumens” per unit of electricity used to produce these lumens. In addition, LED outputs all its light from one side therefore a light fixture doesn’t need a reflector.

- They can last long time. LED manufacturers specify 50000 hours at some pretty high emitter temperature (75-85C) – it’s 11.4 years if lights are on 12 hours a day. At the end of 500000 hours a LED maintains 70% of its light output. The main factor here is temperature of the LED – if it is kept lower than specified the LED will last longer (and produce more light, see below).

As I mentioned before, it was difficult to determine the necessary light output of the fixture I was about to build. For this reason, I started to look at available power supplies first. After browsing through offerings on eBay, Aliexpress and electronics components supplier’s sites I sized my supply at 300W – the power is good and the cost is not excessive. The representative supply is Meanwell model S-320-48. The price is ~US$70 for a genuine one and ~US$30 for a clone. Dealing with clones is involving – at the very least, you’ll need to a) inspect a power supply inside (involves non-destructive removal of warranty stickers, requires finesse), b) test for load and ripple ( requires some pretty specific equipment, like 300W dummy loads), c) burn-in for a couple of days under full load (difficult to do safely in residential setting unless you have an empty 2 car garage), and d) undo the deal if you’re unhappy with one of the previous steps. Buying/returning on the Internet takes time; I suggest not buying from China – transit times are too long. I had to return 2 supplies; the third one turned out to be a genuine Meanwell with a cut-off sticker – for the price of a clone.

A 300W power supply can drive 250 – 280W of LEDs. At present, high-power LEDs are available in 2 flavors – single emitter and multi-LED modules. The big advantage of a single emitter is low price per unit. However, they are harder to work with – to build a 270W light out of 3W LEDs you will need 90 emitters each requiring 2 mounting holes, 180 drilled and tapped holes in total. Also, they come soldered on so-called “star” heatsinks with uncertain thermal characteristics – thermal conductivity of tin is 3.5 times lower than aluminum therefore thermal resistance between an emitter and its heatsink highly depends on the thickness of solder layer under the LED which no one seems to even attempt to control. In addition to this some “LED mounters” use lead-based solder which has even lower thermal conductivity – 5 times lower than aluminum. Another big disadvantage of single emitter LEDs is that it is hard to get a genuine one. Most mounted LEDs sold to me as “Cree” or “Bridgelux” were fake – I have about 30-40 pieces of each name bought from different places. What is interesting is that all Luxeons I have (another 50 pieces) are genuine. Lastly, single emitter LEDs are about twice as expensive per watt – 45W Cree CXA011 from the brightest bin costs US$15.23 at Mouser whereas mounted “Generic 3W Epistar” at stevesleds.com sells for $1.85 (prices at the time of writing), and if we start comparing lumens per watt (assuming that we can reliably determine real lumen output from generic emitter) the difference will become even larger.

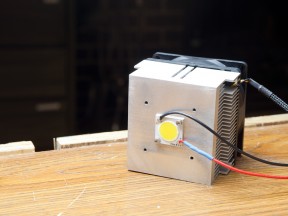

Now that we know that multi-emitter modules are the way to go let’s take a look at what’s available. Chinese make decent modules (search eBay for ’30W white led bead’ to see these good looking products mounted on hefty aluminum bases measuring ~45mm across). I have used them in my past projects – they work well and they are easy to drive, typical forward voltage at 1A being ~34V. The problems with Chinese products are a) the quality is unknown – you can get decent product or a piece from rejects bin, and b) the real characteristics of the device are unknown. After looking further and comparing watts per dollar, lumens per watt and whatnot, I decided to go with Cree CXA2011 module ( Link to the datasheet ). The main reason to pick up this particular module was ease of mounting. The second reason was price. Lastly, the module is available from established US suppliers in manufacturer’s packaging therefore the probability of getting a fake is low. Picture on the right shows the module bolted to a heatsink by a pair of #4-40 screws. My grow light uses 6 of these. CXA2011 has several color temperatures and light output variations, the full part number of ones that I use is ‘CXA2011-0000-000P00J050F’.

I wanted to keep my LEDs as close to ambient temperature as possible. This means I needed forced-air heatsink. The one on the picture is Rosewill RCX-Z80-AL AMD CPU cooler designed for 70W load. It is available from many places for ~US$7.00. It is many times cheaper than “specially made for LED” heatsinks and it works very well. I learned from the reviews that the included fan is good for two years.

An advantage of having a grow light with fans is that air movement in a grow room is beneficial for the plants and 6 fans produce pretty decent wind – strong but not excessive. The disadvantages of having a fan is a) extra current consumption and extra power supply, b) noise, and c) extra maintenance. However, since convectional cooling is not possible anyway I would need to learn how to deal with them.

After mounting a module using Arctic Silver 5 thermal interface material and running it at 1A (the maxumum allowed by a manufacturer) I measured 1C temperature difference between the case of the module and the heatsink surface right next to it. Anywhere else the heatsink measured 22C which was ambient temperature at the moment. It was probably possible to have 2 LEDs per heatsink and still get good dissipation but at the end I decided to just have one.

Up to this point I did all my tests using bench power supply. I learned that at 1A the forward voltage of the module is close to 48V while the datasheet showed slightly less than 46V. It also means that the power consumption is 48W instead of specified 45. I don’t know how this extra power increases light output so I will continue using datasheet numbers for light. I also know that LED forward voltage increases slightly with temperature therefore I need a LED driver which will go over 48V at 1A. The one I picked is Meanwell LDD-1000H. Picture on the left shows 3 drivers mounted on a protoboard. The driver needs at least extra 3V on the input so I tuned up the power supply output to 55V.

When all major components are specified it is possible to calculate the price. Here is a list:

- Power supply, 48V, 312W, Meanwell S-320-48 or similar. $30 for “similar”

- Cree CXA2011-0000-000P00J050F 45W LED modules, 6x$15.23 = $91.38

- Meanwell LDD-1000H 1A 52Vout max. LED driver. 6x$11.52 = $69.12

- Rosewill RCX-Z80-AL AMD CPU cooler. 6x$6.99 = $41.94

The total for the main ingredients is $232.44. The price for miscellaneous small pieces such as fasteners, aluminum angle, polycarbonate, solder, connectors, etc. is hard to estimate (I just have all this lying around); it is still safe to assume that total is going to be $260 – $280 depending on what you have on hand already.

Couple other notes about pricing. First, it is possible to negotiate prices on eBay. Many sellers provide “Make offer” button which you need to use wisely – do not try to offer $5 for $30 power supply since your offer will likely be declined without further discussion. It is much better to offer $20 initially and then add a little during each round. It is also possible to discuss (and lower) shipping charges.

Second, it is easy to scale down this light – just use smaller number of LEDs. You will need to account for other pieces too – a single combination of LED, driver and heatsink costs ~US$35. In my opinion, the smallest number which makes sense is 3.

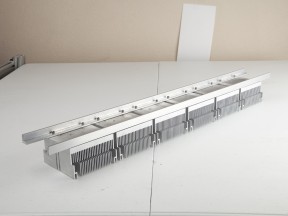

The construction of the light is very simple. The most tedious task is drilling/tapping holes in heatsinks and two 22″ 1/4 aluminum angle pieces. After the main structure (pictured on the right) is put together LEDs with wires soldered on are mounted on the heatsinks. After that it is necessary to cover the LEDs with a piece of transparent plastic to protect the lens – I used 0.118″ polycarbonate. The drivers are mounted on the sides of the structure, 3 on each side. LED wires are soldered to the drivers and zip-tied to the angle pieces. Finally, fans are mounted on heatsinks and wired together. They are powered from their own 12V 1A wall wart at the moment; I’m planning to add a step-down converter to power them from the same 48V supply which still has some power to spare.

Next two pictures show construction details. First picture shows LEDs mounted on heatsinks, wire routing and transparent protective LED covers – again, very important pieces! Second picture offers view from the top showing fans as well as LED drivers mounted on the sides.

I don’t own a photometer so I need to estimate light output from numbers in the datasheet. First thing to do is to determine the working temperature of the module. The datasheet states effective thermal resistance junction to case being 0.4C/W, which means that at 48W the die will be ~20C warmer than the case. I am assuming that all energy in the LED is converted to heat, which is very conservative. Early illumination-grade LEDs converted about 10% energy to light, modern ones are close to 20%. For 20% the temperature rise will be 15C. Now, the measured difference between case and heatsink (given earlier) is 1C – let’s just forget about it since it doesn’t make any difference. Another measured temperature is ambient in my small grow room where this light has been deployed for several days – 30C. Adding 20 and 30 together gives 50C – this is the temperature of the LED die during operation.

We can continue going through numbers in the datasheet or we can take a shortcut by looking at the following presentation, which gives output of 3480 lumens per module at 45W and 85C. This means my light puts out 23040 lumens (page 7). Since my emitters run colder I’m getting more light. How much more? If we refer to the datasheet again (page 5) and analyze flux vs temperature relation we will see that at 50C the light output rises by roughly 10%, which means my light outputs more than 25000 lumens – 25344, to be exact. The difference is equal to 0.6 light output of a LED module; it can be seen that heatsink fans pay for themselves – they consume 12W but add (or save) 27W!

The light has been in operation for several days – too early to notice any effect on plants (and I just started my seeds so I don’t even have any above-ground growth at the moment). However, I noticed that it gives just slight temperature rise in my very small grow room and produces nice breeze. In addition, it is easy to build and safe to operate. Needless to say, I’m very pleased with the result.

Oleg.

hello good day to you. One question on the thickness of wires between 3w hi power led in a line. What is the gauge of wire to use?

I used wires from old PC power supply; it’s about 18ga. The current is 1A max, you can probably use thinner wire.

Hi,

Thanx for the informative guide. I have one question though, why havnt you brought up PAR and wavelength of the LEDs? It seems like peoples largest dilema is finding out what wavelengths to use.

I gave links to Wikipedia PAR article and LED’s spectral output in the post.

I used a different setup. I went with low voltage 24V high output flex lines from flexfireleds. for about $70 after everything. I don’t know my lumens but it’s bright as hell, and with another $400.00 I’ll be near what my HPS was or more. I like them because lower heat can get them within 1/2 inch of plant safely, only 20w/metre. 20m of this turned on and you wont even see my 400hps turned on.

Post some updates, your led bar is pretty nice, like to see how it performs.

It works very well – the plants are happy and grow like crazy. The amount of light is more than sufficient, about twice as much as necessary. The light density is too high – they burn dark-colored paper placed closer than 3mm to the emitter in the light path. I’m designing my next light using 10W chinese emitters. It is going to be water-cooled also so I can trap heat energy released during the day and use it to heat up the plants at night.

Dear Oleg,

What was your setup and result under the lights?

What have you done about the high light density? Have you already tried the 10W chinese emitters?

Thx,

Regards,

Follower

The light density is OK, I don’t think anything needs to be done about it.

10W setup is in the works.

Look up the thread for my notes about the current light performance.

This is great! I am thinking about building one of these for my aquaponic herb garden and I was thinking about water cooling as I was reading the article. Excited to see what your next unit looks like.

I’m pretty energy conscious, any idea how this compares in PAR lumens per watt to MH or HPS lighting?

Should be much better – white LED output is 100% PAR. This light is actually too strong – I had to move it far away from the plants otherwise they won’t grow. I’m now in a process of building a smaller one – 200W which can be regulated down if necessary.

Oleg,

I love this article; thank you for taking the time to document your build. I have a couple of questions regarding PAR and module selection. How did you determine the 100% PAR output of white LED? Is that the case for all white LED light or just this module? Also, upon reviewing the data sheet for the CXA2011 module I read the ‘Relative Spectral Power Distribution’ chart/graph. As per this graph, 3000K,4000k, and 5000k CCT modules were shown to produce the maximum power within the wavelengths most notable for plant growth. Would utilizing a mixture these three modules be superior than sole use of the module you listed, or would PAR be affected in a detrimental manner?

Thank you in advance and I apologize for my ignorance in this subject.

Regards,

CJ

All the light emitted by white LED is in PAR. This affects the “usable lumens per dollar of electricity” factor. PAR itself is not that critical – plants grow well under the Sun, which is 50% PAR, or under HPS, which produces mostly yellow and IR, or under any other source with sufficient light output.

The module I use has the highest lumen output plus I like this color temperature.

Hi there,

hope you can help me, i have been searching the web and have look thro many a design, i like yours but what if i wanted to make your design but using red blue spectrums for photosynthisis, can you recomment a suitable led, i cant see that cree have one, or am i missing the link, and what ratio would you use, thanx in advance

I heard that the ratio of red to blue output should be 80/20. I’m not aware of any high-power ( more than 10W ) reasonably priced red emitters.

thats the end of that one then…lol. if i used 36 x 3w leds, powered by 3 seperate drivers, each driving 12 leds each (3 x 36 watt drivers) would it matter in your experience that the selection of leds that make up my 36, will be of different specs….they would all be 3 watt, but when i look at the specs in detail, all the forwarding volts and currunts ect…..are different.

nd would you reccoment resistors or are they not needed, as i am wiring in seris..

…sorry to sound like a novice..

,,but i am, and want to at least get some parts ordered.. as you will appriciate, they cost a bit and i want to get it right.

Hi Oleg,

Wouldn’t it be more cost effective to have a bunch of (series) of low power (cost per lumen being low) rather than a few ‘power’ LED unless there is a specific reason for the plants to have a concentrated single point light source. In the case of low power SMD LEDs you probably wouldn’t need a separate heat sink or forced convection as the total heat produced will be carried away with natural convection from the PCB surface. Or am i not getting it!

T

5mm white LED outputs less than 2 lumens. You’ll need 500 of them to replace a single CXA2011. The cost will be similar but you’ll then spend a lot of money mounting them.

I found your right up extremely useful. Thank you.

When / if you do this again (and again 🙂 ) would you use the same light array and LED drivers and if not: 1) why not 2) what would you use (or think would work better and why).

THANK YOU!

Also,

I’m (easily) confused. You note:

“LED outputs all its light from one side therefore a light fixture doesn’t need a reflector.”

The data sheet notes a viewing angle of 120 degrees. Have you thought of adding a lens to restrict the angle to focus the light better on your plants?

I haven’t seen lens made for this particular module. Besides, the same effect can be achieved by hanging the light closer to the pants.

Thanks so much. Would you use the same lights if you were building this system today?

I am thinking of using the CXA1512 series. Lower Watts and voltage/Amp’s.

Less lumen, but I want to put all 5 color temp’s onto a single heat sink. 5k – 2.7k.

I am making sure to have roughly 30,000lm for veg and 60,000lm for flower.

Was going to use 9 heatsinks, each with 5 LED’s a piece. Each LED will be a different color temperature.

If that would not work, can you recommend a heat sink that might work with 5 LED’s at once. I used the minimum Lumen @ 85C to determine my Lumen totals.

Thank you!

which heatsink? And why do you want to use all color temp.variations?

The one you suggested. The rosewill.

To ensure a very nice Wavelength spectrum. adding the 2.7k and the 3.5k is overkill probably. But I really feel that the 5k, 4k, 3k would all be great for a broad spectrum of wavelenhts. From the Blue’s and greens for veg, and the Orange and yellow’s for flower.

This is 100W heatsink. I’m runnung one 50W LED on it and it is slightly above the ambient. You are going to run 5x24W LEDs; I really feel you will be overheating them.

Well then, do you know of a heatsink designed for 200W, something that could efficiently dissipate the heat?

I don’t, sorry.

Rosewill RCX-Z200 92mm Ball CPU Cooler – It has 3mm more surface area, as well as 6mm increase in Fin height. That is a rather large increase in heat dissipation.

Any suggestion for a smaller AC line to DC power supply for someone who want to use just one of these leds in this fashion?

If you keep the LED cool the power will be close to 50W. Meanwell has plenty of AC LED drivers in this range. 1A, 50V or more. Don’t buy Chinese.

Hi Oleg , I really like your design. It seems very straight forward and simple without a huge amount of work. I do alot of tomatoe growing with HPS lights and have been very interested in LED lighting due to heat problems. I have notices that most Led grow lights tend to have arrays of red and blues instead of white. Is there a reason you went with white instead of specializing in a particular set of wavelength in order to maybe have bigger and better yielding plants. I could be way over my hear so sorry if this is dead wrong. Thanks for your time and advice.

From experience (mine and many others) it seems that for the purpose of growing intensity of a light is more important than any particular spectrum. See Sun spectrum, for example, or the spectrum of HPS lamp. There is a reason not to emit in green band and only use blue and red emitters, however, decent (i.e., non-chinese) high output (10w+) red LEDs are impractical for growing – what I’ve seen so far is ~3x more expensive than white ones with just slight increase in efficiency.

Thanks for the reply! I see now , you said that for your next light you would move towards 10w lights? Why is this? Also what kind of results did you receive with this light? From the limited amount of research and reading I’ve done it seems the Cree lights are some of the best in the industry at the moment.

I want to try 10W Chinese lights to see a) how they compare to Crees and b) how long they will last. This is the project for the winter though, right now everything grows outside under sunlight.

Results were good so far – much better than fluorescent of comparable power. This coming winter I will be running a lot of experiments with indoor growing.

Could you use 1 driver if you ran the LEDs in series? I want to build a four square light. Thanks for posting. I think those 45 watt emmitters look amazing compared to my current 3w setup!

A single CXA2011 drops ~45V. Four in series would require 360V driver. I don’t think anyone makes such a driver.

Have you seen the new CXA3050 LED’s? They are extremely efficient and produce over 5000 lumens at 50W at 1.4amps and over 10000 lumens at 2.5 amps.

Yes. I’m planning to try them sometimes. Have you found a good driver for them?

I just ordered a driver off ebay that does 1500ma and up to 40V so that should be just fine. I’ll let you know how it works out

Hey Brian, I know this is probably a novice question, but did you just hook the driver to the led and then run directly into the wall plug, or did you also have a power supply between the wall and the driver? I’m just trying to get my head around this stuff.

Thanks for any help.

Meanwell sells some nice drivers that can push the LED’s from 50 to 100W by adjusting the current on the driver. The current ranges from 1.4-2.25A which is the perfect range for the CXA3050 LED.

Check out HLG-100-42 and CEN-100-42. The HLG is slightly more expensive as it is the most efficient driver line from Meanwell.

It would be cool to have the flexibility to over drive the LEDs for certain times of the growing cycle, specifically later in the fruiting stage and then dial it back down when you don’t need as much light.

HLG has ouput power adjustment – it would be easy to make variable output light.

Brian,

Which of the CXA3050’s are you looking at? I am thinking the 3000K, 93 CRI have a better photosynthetic spectral distribution, so maybe the CXA3050-0000-000N0YV430F or CXA3050-0000-000N0UW40E3. Do you think it is better to loose a little flux but gain spectral distribution?

I got the 2700K from digikey (CXA3050-0000-000N00W227F-ND) that were rated at 5683 lumens, so I should get well over 6000 lumens per running at 1.5amps and having them air cooled (approx 10-20% increase). I would always prefer more intensity than spectrum just as HPS is really intense and does wonders flowering, despite it’s limited color spectrum.

I’ll begin testing my light out this week and will report back as I will be able to compare how this light did, to my existing DS100 LED light

Brian, where did you find CXA30 holders?

Just to let anyone know, you can get solderless holders for the cxa30 series on mouser.

http://www.mouser.com/ProductDetail/TE-Connectivity/2-2154857-2/?qs=%2fha2pyFadugAgPLTaG4bmekBcEb4TFyEA6KuG77EqLSR07yT7niOiA%3d%3d

Mouser has it listed as only fitting the citizens electronic array family, but when I looked at the manufacture’s site here

http://www.te.com/catalog/pn/en/2-2154857-2

It has it listed as compatible with several different arrays including the CXA30 series.

Hope it helps.

I am in the process of doing (somewhat) what Brian did. I just ordered two cxa3050’s, one in 5000k and another in 2700k in hopes to give a fuller spectrum for my plants. I also purchased the driver he specified on ebay. Now just to wait for shipping and figure out the rest of what I need.

Thanks for the info!

Oleg,

Thanks so much for this post. Nice work! Can you tell me where you purchased the cxa2011? All the eBay sources are in china. Thanks

I bought mine at Mouser – http://www.mouser.com

Really? Perhaps the price went up then. I found that but the prices listed are $25.71 (for 1)or $24.75 (for 10). Hmmm. Seems you may have created a demand. 🙂

Am I wrong or are these exactly the same even though the part number is slightly different?

http://www.todaycomponents.com/cree-cxa20110000000p00g00e8.html

The devil is in the details. After manufacturing, high-power LEDs are sorted (binned) by light output. Slightly different part number could mean the part with the worst output.

Oleg,

Would you give us a little more detail on your driver assembly and mounting? Thanks

It’s pretty simple. You wire one side of the driver to a power supply and the other side to the LED. I combined 3 drivers on a piece of a protoboard. Blue terminal is for power, all 3 drivers are wired to it in parallel. LED wires are soldered to the driver, there is no connector for them.

What did you use to thread the holes in the heat sinks?

I threaded using regular 4-40 tap.

Do your LEDs put off a decent amount of downward heat near the LED light? If I put my hand really close to the CXA3050, it gets really hot.

I have them attached to large heat sinks with air blowing on them and the heat sinks are cool to the touch.

I know the heat sinks are working because if I turn the fans off, then the heat sinks start getting hot.

I was just surprised how much downward heat is actually coming off.

Do you experience the same thing with your LEDs?

If you place a piece of magazine paper close to the LED it will start smoking. Still, it’s not as intense as HID.

The photometrics (IES) of this LED has a circular shape around 24″ diameter from the source, which means the widest spread of light occurs about 12″ from the source and intensity diminishes as the light gets further away. I was wondering how far you are placing the light from your plants was wondering what you think of spacing the LEDs further apart to maximize the efficiency of this spread?

Page 5 of the LEDs Data Sheet shows Relative Spectral Power Distribution and I was also wondering why you choose a 5000K CCT over a 3000K CCT which has a higher % in the 600nm to 750nm range?

The emitters I used have the highest light output in the series. I believe the output is more important than spectrum, plus “warm” LEDs are more expensive.

It is easier to create uniform illumination by using larger amount of low power LEDs, however, finding good low power LEDs ready to use is significantly more difficult. I like CXA0211 devices because they can be mounted easily, the thermal resistance from die to the package is specified and they come in factory packaging so I know who made them.

The CEN-100-42 (not to mention the HLG-100-42) power supplies are really expensive, and for only one led, would you say it’s worth the cost to buy them instead of the S-320-48 you used for this article?

I’m thinking on doing the same setup as you, and then start trying things and improving in small steps (leds, power, cooling)..

The drivers I used are pretty cheap, however, they output 1A max. If you need more current per LED you have no choice but to use mains-powered drivers, which are more expensive.

I grabbed some 50W (37-40V 1.5A) drivers off ebay for $17 a piece. They seem to work well and I have pc case fan blowing over them to keep them cool.

They were also shipped from USA

The CEN-100-42 and HLG-100-42 drivers would be able to drive 2 50W LEDs, so take that into consideration

http://www.ebay.com/itm/AC-85-265V-DC-25-40V-50W-50-Watt-LED-Light-Bulb-Driver-Power-Supply-Transformer-/271211624474?pt=LH_DefaultDomain_0&hash=item3f2578f81a

Here’s the drivers I grabbed

Oleg,

I am trying to follow your build and I just received my CXA2540-0000-000N00U427F from Mouser. The LED has no holes. Did you actually drill a 2 holes in the LED corners? How did you hold the LED while drilling?

Thanks!

I didn’t drill holes in the LED – CXA2011 has them. I don’t think drilling is a good idea, try to find holders for your LEDs, similar to this one -> http://www.molex.com/molex/products/group?key=chip_on_board_cob_led_holder&channel=products

Thank you. I was thinking about making a bracket like that myself, but wasn’t sure about high-temp material to use. But this is much better.

You could also get some thermal adhesive if you didn’t want to thread holes

I want to experiment with couple different passive heatsinks, so I would like to avoid glue/epoxy

NOTE to anyone who is building using newer CXA2540 modules: You have to buy an “LED array holder”. Mouser has them in stock: http://www.mouser.com/Search/ProductDetail.aspx?R=180720-0001virtualkey53810000virtualkey538-180720-0001

I just got my light meter today and holy cow do these CXA3050 LED’s throw off some serious intensity.

I was getting over 100,000 LUX 4-5 inches from the LED and over 30,000 LUX around 14″ away.

I compared the 2 CXA3050 (100W Total) intensity to a 150W HPS intensity and the HPS doesn’t even come close.

I barely got 50,000 LUX if I put the light meter directly under the HPS (granted the HPS is air cooled so some intensity is lost through the glass).

I was getting 50,000 LUX around 10-12 inches with these LED’s

I am very excited to see the growth since these LED’s also have really good PAR ratings and intensity.

For a CXA2540/CXA3050, Could you write two of the LDD-1000H outputs in parallel to get a 2A max drive current?

I don’t think so.

Good post bro been so much help I have been looking to make my own led grow panel but with 3w leds. 120 leds total 60 on each panel. Im looking at a 48V 10A 480w power supply. I want to run the fans with the 3rd output. What do i need to not burn out the fans that run off 12v? Does every output only have 160w?

You’re asking about power supply? What’s the make/model?

http://m.ebay.com/itm/121188166667?cmd=VIDESC

New 48V 10A 480W Switch Power Supply Driver For LED Strip light EP98

This is the one i had in mind. Because the price of a 120w constant current driver is about $40. These are $51 shipped. And has more power than i would need. This is my first try at this and i am pretty post.

This one only has one output. Be careful with Chinese supplies. You can’t just use one out of the box, you need to open it, inspect the assembly and then load test it. I also suggest having a spare one handy unless you don’t mind losing your plants.

I already have led lights but i wanted something high power and custom. All i really need is a 360w and about 38V driver. I only wanted the 480w because I thought the power was divided in channels like a car amplifier. Im looking for something like the Mean Well you used for this project but maybe something a little more powerful.

Hi Oleg , how did you wire the CPU fans and leds? Thanks

LEDs are wired to LED drivers. Fans are running off of separate 12V wall wart. Later I developed a buck converter which can be used to generate 12V with input voltage up to 60V, I’m going to try it in the next build and post the scematic if I like the performance.

hey oleg!

i plan to build a grow room 4m x 4m. i will go aeroponic. my chambers size will be 0.54m L x 0.54m W x 1m H. i will use 20 chambers so my growing area will be 5.9m2 imagine a grid of 5 rows and 4 columns. i was so detailed because i think to redesign your panel. my idea is to put a heatsink with a 3 CXA3050 over every chamber. imagine something like a grid from aluminium bars 2cmx2cm and on every corner, ” T ” or cross attach the heatsink. maybe it can drive the light straight to every plant and if you need to expand the system is easy. from quick calculation and based on that every m2 are 500 W for led (1000w for hid) i need 150w per plant. its sound expensive but in one or other way you need this amount of watts for this coverage. any comment opinions?

thanks

Are there any tips on soldering the wires to the cxa2011 terminals? I can’t seen to make them stick.

You’ll need a large soldering iron tip. I’m using the largest available for my Weller WES51. Oh, and you don’t want your LED mounted on a heatsink.

Get some solder paste flux and that will really help to make the wires stick to the chip

I believe you previously stated that the grow light was almost too bright in a previous response. Would you think using CXA1304s and spacing them further apart could amend this and perhaps give a larger grow area for the same wattage?

I don’t think it’s a big deal – just move the light away from the plants.

Oleg, great article! Thank you very much.

What do you make of Cree’s new CXA3070? Should those be used instead of the CXA3050? Also for total beginners, could we ask you to make a quick tutorial on how to build a light with two of these in action? Serial or parallel?

It is all rather confusing and exciting for us newbies!

Tim

I haven’t looked at new ones. The CXA2012 is somewhat easier to mount. Running these modules in series will give you ~100V forward voltage for series of 2 and it will be difficult to find a driver capable of providing that much voltage. Parallel is a bad idea.

When you build a grow light the goal is to get max. lumens per dollar – both in capital and operation expenses. My architecture, i.e., a single power supply plus one driver per LED module seems to be the most cost-effective one.

Great read, easy to follow. Thank you.

After reading your article, I put together a square of four using your recommendations for LED, heatsink and driver. 6 just sounded like too much. After 3 weeks of being over the top of my plants, i have noticed a very pronounced activity of growth.

Bill

Nice build. Thanks for the information provided. I like what you did and i am trying to do something similar. But i am stuck with choosing the right power supply/driver for my leds.

I have

20 X red 3w leds 630nm, typical forward voltage 2,4 at 750mA

12 X deep red 3w leds 660nm, typical forward voltage 4,5 at 300mA

3 X cool white 3W chip typical forwarding voltage 3,5 at 700mA

3 X warm white 3W chip typical forwarding voltage 3,5 at 700mA

3 X Royal blue 3W chip 450nm typical forwarding voltage 3,5 at 700mA

2X far red 3W chip 720 nm typical forwarding voltage 2,4 at 350mA

So first of all do you think this is a good setup?

And second how do i power these leds.

Can i use one of these and try to power them all with it?

http://www.ebay.com/itm/360W-Switching-Switch-Power-Supply-Driver-for-LED-Strip-Light-DC-12V-30A-/380747265289?pt=UK_BOI_Electrical_Test_Measurement_Equipment_ET&hash=item58a64e3509

If not please try to explain what else shoud i then do.

Thank you.

In my opinion, low power LEDs are too much work.

I agree with Oleg. My 2 CXA3050’s are doing amazing and I have the ability to drive them even further if I wanted to.

However, if you want to do individual LEDs, personally I would model a build after the area 51 LED lights or the apache tech lights.

Those only use whites/reds.

You could build an amazing light using just cree xml-u2 white leds with cree 630nm red leds. Perhaps toss in some orsam 660nm leds as well.

I would only use the the far red for flower initiation. Having far red in your spectrum the only time can create a “shading” effect which causes plants to stretch like crazy.

Don’t forget about UV as well, but that can easily be supplemented with reptile bulbs

Sweet build. I am shamelessly basing my build on it. I am a complete newb but I am having fun learning.

With that said, I see that some of the MW drivers appear to have 2 output channels. If the driver is a LDD-500H, for example, does that mean each channel can support 500mA to a single LED (or chain)?

I want to drive 6 CREE CXA1507 5000K LEDs on 3 heat sinks similar to the ones you show. Would I need 3 or 6 of the LDD-500H drivers?

I think that would work out to around 86W total. What kind of coverage area do you think that would cover based on your experience with your build?

LDD driver only has one output; it has 2 pairs of output pins to handle more current.

I’m still figuring out the coverage. The light doesn’t look particularly bright but plants are very happy. I know that 280W is likely too much for 9 sq.ft., don’t know the “too little” side yet.

Forgive me if this is a foolish question.

You say, “it has 2 pairs of output pins to handle more current.” Does this mean that each set of pins, on this driver, can output 500mA, or does that driver only put out 500mA total (eg. 300mA on one set and 200 on the other)?

It’s neither. There are two output pins, Vout+ and Vout- . Two adjacent pins are tied together. The same is true for input.

Can you suggest somewhere that sells all of the items and will ship to UK?

now sorted

I’m confused about the usage of the term “driver”. The main article makes it sound like the setup goes:

PSU > LED Driver > LED

But everyone in the comments section is referring to things like the HLG-100-42 as drivers. How do you go about connecting that to the setup above? The data sheet for the HLG-100-42 makes it sound like it’s a PSU since it says it takes VAC input, like from the mains. Does that mean it’s really a PSU and I’d still need separate LED drivers? Or do people call it a driver because it is a PSU+driver combo unit?