While making some measurements today I noticed a strange reflection in the signal generated by my Tektronix 7S12 TDR sampling plugin. At first, it looked like a bad connection at the output of the loop-through S-6 sampling head, however, after further testing it turned out to be more serious flaw. The following two screenshots show the reflection: the left one shows the step into terminated S-6 and the right one shows the same step with terminator removed to give me the reference for the distance. Apparently, the reflection occurs inside the head itself!

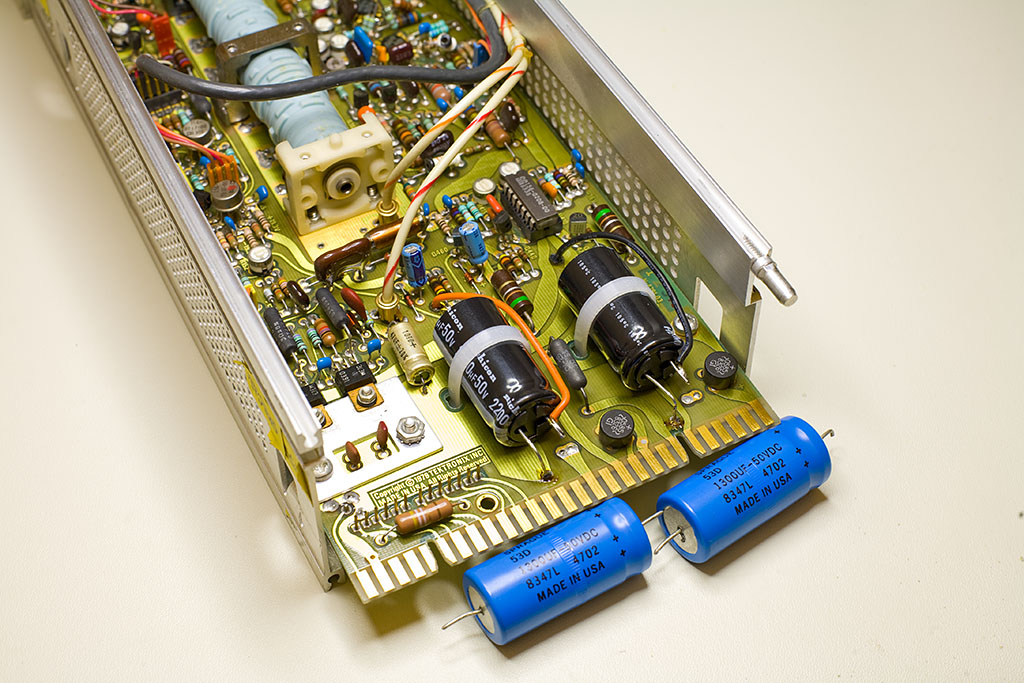

I pulled the head out and took it apart. It was rather easy – after removing 3 screws on the back the head internals slide forward from the case. The picture on the right shows the guts of the sampling head with preamplifier board removed. The square metal box next to the faceplate with two SMA females sticking out of the back is a hybrid sampling bridge and according to the distance to the reflection this is the place where I need to look.

Further disassemby is easy. First, 3 socket head screws need to be removed along with the board they are holding. After this is done, both male SMA connectors need to be unscrewed. Lastly, after unscrewing two nuts on the faceplate the bridge can be freed from all obstacles and taken apart.

Luckily, taking the hybrid apart was not necessary this time. I discovered that one of SMA connectors (upper left on the picture) came loose so I simply tightened it up, assembled the head, placed it back into 7S12 and observed a nice step with good corners and no extra reflections. The whole project took less than an hour, most of the time spent taking pictures.

I’m a happy time-domain reflectormetrist again, writing this article hoping it will be helpful for someone. Next time your sampling head starts acting funny don’t run to eBay for the new one (and I checked – they are out of S-6 at the moment). Take it apart and look inside – you may be able to fix it, even though in my case it was more by luck than judgement.