|

|

By Oleg Mazurov  Fan regulator

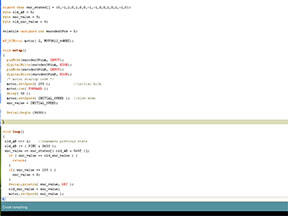

This simple mod, originally described by tinhead on EEVBlog forum, is intended to make built-in cooing fan quieter. Typical problem with cooling fans is the noise they make and typical solution is to decrease voltage (and therefore current) to the fan to make it rotate slower. Hantek DSO5000-series oscilloscopes have 3 terminal 12V regulator dedicated for the fan (pointed at by an arrow on the title picture). To change the fan voltage I simply need to replace the regulator marked U7 on the power supply PCB.

Tinhead’s original mod was to replace 7812 (12V) regulator with 7805 (5V). It will work assuming good quality fan. Mine refused to start from 5V so I used MC7808 – a 8V regulator. Another good candidates were 7806 and 7809 but after first try I decided 8V is good enough – the fan is spinning well and the noise level is low.

The following picture shows power supply PCB unscrewed from the chassis and turned upside down. Again, an arrow shows the regulator. The PCB is single layer; replacing the regulator is a simple matter of removing solder with a solder wick, pulling the original regulator out and soldering on the replacement. If everything is at hand, the mod takes about 15 minutes to complete, including testing.

Enjoy!

Oleg.

Bottom side of the PCB

By Oleg Mazurov

|

In previous article I started talking about constructing magnetic stirrer from PC fan, a pair of rare earth magnets, and plastic can. In this article I will show the rest of the construction as well as program code to control the motor.

When building cases for my designs, I tend to avoid techniques requiring accurate (read “any”) measurements and calling for non-round holes. The design that I’m describing here is no exception. In order to complete it I needed just a few extra parts in addition to plastic joint compound can, PC fan and magnets, arrangement of which was described earlier. I used Arduino controller equipped with Motor Shield from Adafruit to supply PWM current to the fan, 3 nylon standoffs with adhesive bottoms to mount Arduno, rotary encoder to set stirrer speed, and panel-mounted 2.1mm DC power jack. The stirrer is powered from 12V wall wart capable of supplying 300mA or more.

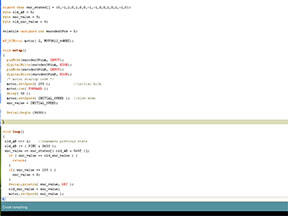

I was thinking of implementing monitoring of motor current to track the moment when stirrer bar loses attraction to the magnets and stops rotating. When I was playing with the stirrer powered from bench suplly the change in current was quite visible. However, I found out later that when motor is supplied with PWM signal, current stays almost constant over the whole range of duty cycles and loads and current tracking won’t work. With regret, I abandoned this clever feedback idea. On the bright side, the code necessary to control the stirrer immediately became much simple, short and easy to understand.

|

Stirrer code |

Continue reading Vigorius stirring redefined. Part 2 – electronics

By Oleg Mazurov  Tornado in the flask Magnetic stirrer is a handy tool to help in any household activity, where agitation or mixing of relatively small (under 4L/1Gal) volumes of liquid or suspension are involved – from yeast starter preparation to dissolving fertilizer to chemical experiments. As almost any piece of laboratory equipment, factory-made magnetic stirrers are way overpriced. At the same time, such stirrer is rather easy to make from junk lying around the house. There are plenty of information on the Internet describing building mechanical part of a stirrer. Google for other people’s projects, some of which are much nicer than mine. I started this project mainly to play with motor control piece so mechanical setup was simplified as much as possible. As far a motor control goes, the main difference of mine will be ability to track stirrer bar behaviour. When a bar is spinning close to the maximum speed for given viscosity, it tends to lose strong attraction to the magnet of a motor and stop. Usual remedy is then to slow down the motor until it catches the bar and slowly increase the speed. Since moment of losing attraction is easy to register by monitoring current to the motor, the process of catching the stir bar can be automated. Also, I have a suspicion that a current change will be observed just before the disconnection and can be avoided altogether by corrective action. I will check this possibility during control circuit firmware design. Now, while waiting for Adafruit Motor/Stepper/Servo Shield for Arduino kit to join piles of junk lying around the house, I will describe mechanical implementation of the stirrer.

Continue reading Vigorius stirring redefined. Part 1 – mechanics.

|

|